The pandemic has caused an economic crisis and disruption across many industries – forcing businesses to rethink how and where they conduct operations. In the face of these changes, the printing industry continues to move forward, developing new techniques, technologies, and approaches to customer attainment and retention.

The status quo in printing will never be the same. Still, by recognizing the current production printer trends and understanding how to use them, professionals in the printing industry can continue strong operations. They can do so with fewer layoffs, safer working conditions, and streamlined workflows.

To help your business stay ahead of the curve, here are the top nine production printer trends for 2024.

1. Digital Printing

Digital printing provides a convenient, affordable, and efficient way to print from a digital-based image directly to a variety of media, including paper, fabric, and plastic. With digital printing, there is no need for costly setup or plates, making it ideal for short runs and personalized prints.

In 2024, the digital printing market is projected to be worth $33.43 billion, with an expected increase to $45.93 billion by 2029. This growth is due to the rising demand for on-demand printing, customization, and personalization in various industries, such as packaging and textiles. Digital printing technology is rapidly evolving, with equipment costs anticipated to decline even further in the coming years.

Key Takeaway: Consider a Digital Printing Press

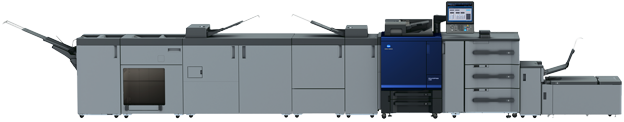

If you want to leverage the benefits of digital printing this year, consider the AccurioPress C4080. This powerful digital printing press allows professionals in almost any industry to increase output while delivering color quality and cost efficiency.

2. Eco-Friendly Printing

Sustainability remains a trending topic across all industries, and production printing is no exception. Companies are adopting eco-friendly print practices, including using sustainable materials and reducing waste. Transparent sustainability efforts are not only good for the planet but also resonate positively with consumers who are environmentally conscious.

One of the ways that businesses have enhanced sustainability and reduced waste is through on-demand printing for customized materials. Previously, companies would have to place large orders to keep prices down; now, businesses can order what they need. If changes are required at a later time, there are far fewer materials going to waste.

Printing facilities are also implementing in-house recycling centers to reduce waste. These centers can decrease wasted paper, ink, cartridges, and other byproducts of the printing process.

Key Takeaway: Implement Sustainable Printing Practices

Businesses can join this trend through various efforts, such as reducing paper jams in their printer. Here are some additional tips:

- Use eco-friendly ink

- Track printing to limit waste

- Implement double-sided printing

- Upgrade legacy copiers and printers

- Recycle empty toner and ink cartridges

3. Variable Data Printing Capabilities

Businesses highly involved in advertising often use mailers and other printed media to increase brand awareness, advertise products, and entice new customers. Previously, these printed items were all the same, but with Variable Data Printing (VDP), companies can create customized messaging for specific recipients. VDP uses software and data spreadsheets to automatically change the output of a digital printing press, making adjustments to personalize messaging.

For example, an auto dealer could use VDP to create customized mailers with individual customer names and vehicle types. Mailers for people who purchased SUVs could have images of SUVs, while mailers for customers who bought trucks can have images of pickups.

Key Takeaway: Use VDP to Offer Personalized Printing Services

Print shops can offer their clients the ability to personalize each piece of printed material, making it more relevant to the recipient. Personalization can significantly increase customer engagement and response rates for clients' marketing campaigns. By incorporating VDP into their offerings, print shops not only provide a high-value service but also put themselves at the forefront of modern printing technology, enabling them to meet the evolving needs of marketers and businesses.

4. Advanced Inkjet Technology

Inkjet technology has made significant strides, offering superior quality prints at faster speeds and lower costs. The development of advanced inkjet printers capable of handling various substrates is a game-changer for businesses that want to diversify their product offerings without compromising on quality. It's a trend worth investing in, especially for companies looking to expand into new markets.

Key Takeaway: Consider High-Speed Inkjet Printers

If you want to improve turnaround times this year, consider the Konica Minolta AccurioJet KM-1. This LED UV InkJet press combines the speed and flexibility of offset presses with the digital benefits of variable data printing. It features automatic duplex printing with no drying time and can print 3,000 sheets per hour.

5. Digital Label Printers

Instead of being on the waiting list of a busy printing firm, businesses are taking their printing efforts into their own hands, implementing digital label printers as part of their operations. Every physical product needs a quality label, and these printers make it possible to print short-run packaging. Digital label printers provide numerous benefits:

- Produce high volumes of labels conveniently and quickly

- Decrease turnaround time as businesses are not delayed by label printing

- Enable on-demand results for special events, promos, and customer personalization

- Increase customization over traditional label printers with set colors, cuts, and formats

Key Takeaway: Bring Label Printing In-House

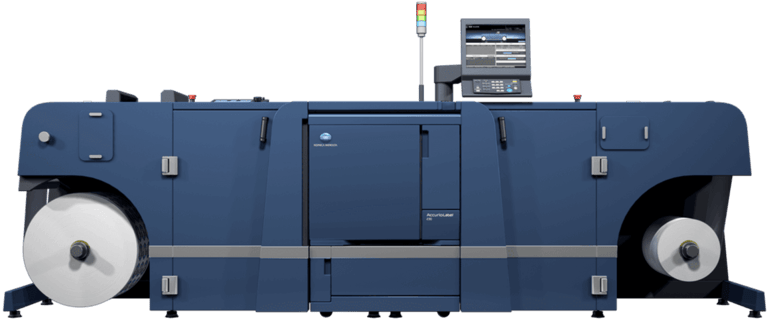

Organizations can take advantage of this production printer trend with the AccurioLabel 230. This high-performing digital label printing press is the third redesign of Konica Minolta’s toner-based printer series, offering higher speeds on tack paper and tack films.

6. Embellishments and Decorative Effects

Companies and consumers expect more than a blank sheet of paper with a few words and stale imagery. In 2024 and beyond, embellishments and decorative effects will continue to be a popular production printing trend as businesses look for ways to make their printed materials stand out in a crowded market. This trend involves adding special decorative effects such as spot UV coating, 3D embossing, and hot foil stamping to printed items to enhance their visual appeal and tactile quality.

Key Takeaway: Consider a Print Embellishment Solution

The AccurioShine 101 allows companies to add dimensional sensory textures to printed products. It can add automatic varnish and hot foil for enhanced visual results.

7. Substrate Versatility

Substrate versatility refers to the ability to efficiently print on a wide variety of materials including but not limited to:

- PVC

- Linen

- Canvas

- Cardboard

- Foiled paper

- Textured stock

- Non-woven fabric

- Self-adhesive label

- Synthetic materials

- Coated and uncoated paper

The ability to print on a variety of substrates provides a competitive advantage for print service providers, allowing them to meet a broader range of customer needs and diversify their offerings. Examples of substrates that can be used with the AccurioShine 101 include paper, cardboard, synthetic materials, plastic, and more.

Key Takeaway: Invest Strategically to Expand Capabilities

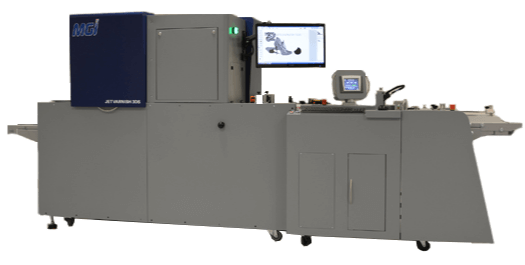

The Konica Minolta MGI JETvarnish 3DS improves the printability of substrate material, regardless of the printing process. It can print matte and glossy surfaces, layered paper, plastic, PVC, and other coated materials.

Embracing Production Printer Trends for 2024

As organizations grapple with the ever-changing print landscape, the key is to stay flexible. Figuring out how to remain a viable production print business or in-house facility can be difficult, but knowing the industry trends can help determine the next best steps and guide teams as they adapt to the new demands of production print.

Get in touch if you need industrial printing support. An experienced print specialist will help you select suitable equipment that offers unparalleled speed, superior image quality, and robust endpoint security.

Editor's Note: This post was originally published on August 31, 2020, and has been updated for accuracy and current best practices.